Meta Description: Forklift trucks can improve warehouse productivity and efficiency, but they also pose safety hazards. These 5 safety practices will ensure employee safety at all times.

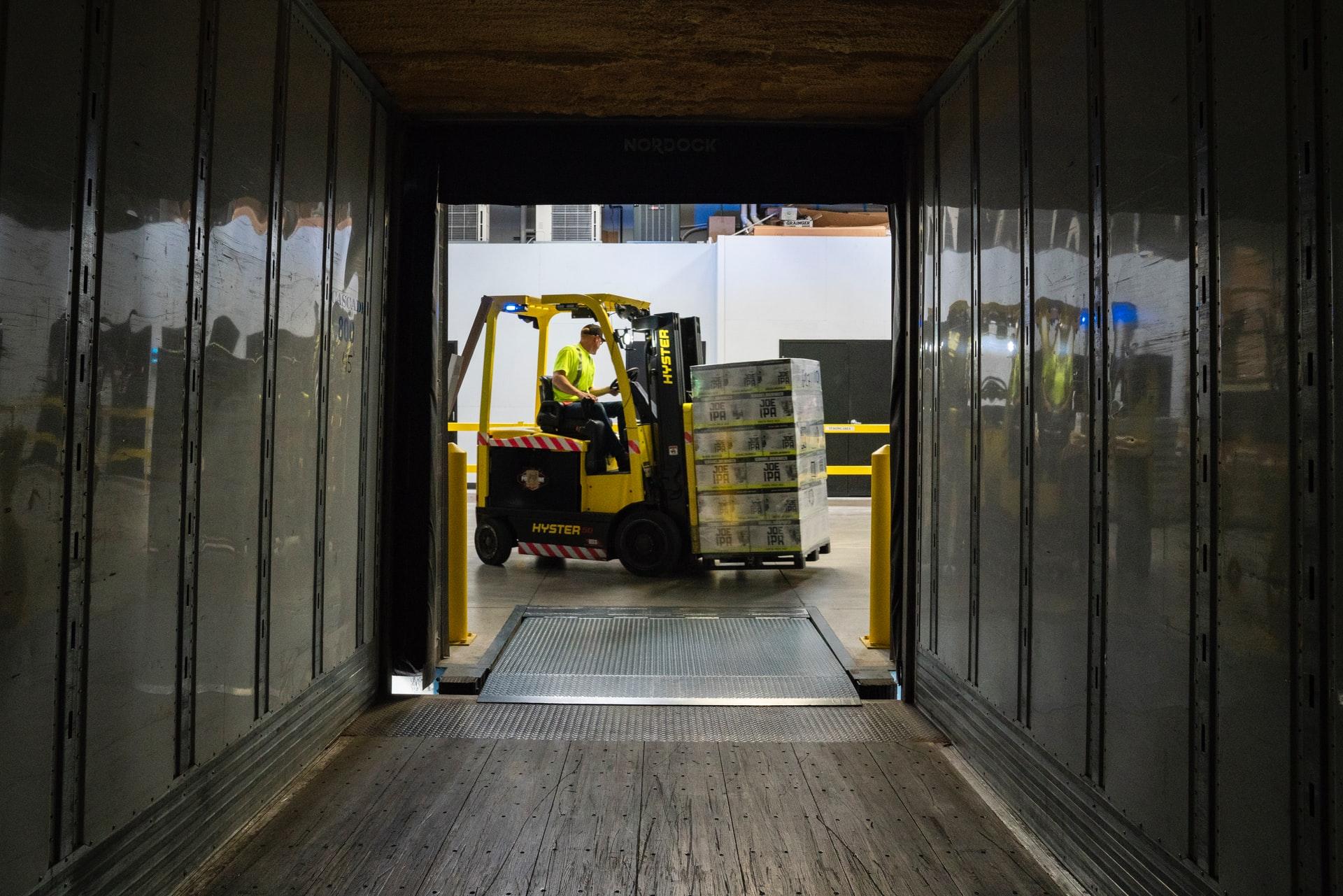

The forklift is a frequently used equipment in industrial workplaces. Also known as industrial trucks, forklifts are indispensable in warehouse operations due to their lifting and transporting functions. They can handle loads with deft and precisions.

However, while forklifts are useful, like any other industrial machine, forklift operation involves safety risks. Crews working with and around forklifts require proper training and education on safety measures.

The Occupational Health and Safety Administration (OSHA) pegs that about 34,900 serious injuries and 85 fatal accidents related to forklift operations happen every year. Roughly 25 percent of these accidents are attributed to inadequate staff training.

To prevent untoward incidents, it’s crucial to understand and observe safety practices in forklift truck operations. Avoid putting yourself and others at risk of accidents with these safety practices:

1. Inspect forklift daily.

It’s a basic protocol to inspect forklift trucks daily prior to every use. The shift supervisor must conduct routine checks to determine and record any truck defects and other problems. Equipment that needs prompt repair should never be operated.

Among the few things to check are:

- Operating controls including brakes, horn, lights, and steering wheel

- Mast and overhead guard for damage

- Possible oil, water, or radiator leaks

- Tire and fluid levels (i.e. brake, coolant, engine, fuel, and hydraulic)

- Make sure forks are in good working order (are straight and no cracks/distortions)

- Other potential hazards

2. Have a floor marking system in place.

A floor marking system is useful in promoting worker safety, Use yellow marks to warn of physical hazards, like falling, stumbling, or tripping hazards; and red marks to distinguish fire hazards and equipment as well as emergency switches. Put wayfinders and signs all over the site to remind pedestrians to steer clear from forklift paths, direct forklifts to safe routes, and smooth out traffic flow.

3. Know and comply with the requirements.

Before any worker operates a forklift truck, make sure they undergo safety training in Toronto under OSHA requirements and have been evaluated with contractor pre-qualifications (Contractor Pre-Qualification Management Systems). OSHA emphasizes the following standards for industrial truck operators:

- Forklift operators must undergo training programs on safe truck operations, the type of vehicle used, responding to a forklift and industrial truck hazards, and OSHA’s safety requirements.

- Operators must be properly trained to execute the job safely in accordance with workplace evaluation.

- Employers must give formal and practical training to forklift staff using various training materials.

- Operators must be certified after receiving necessary training (done at least once every three years).

- Employers must assess the operator’s performance and ensure the employee is skilled enough to operate industrial trucks.

- Employers must have a staff member on duty adequately trained to give appropriate first aid in the event of an accident. They must also be adequately supplied to treat injuries. This is a recommended site to acquire first aid supplies from if you do not have a compliant kit.

4. Ensure forklift stability.

Prior to driving a forklift, ensure your hands and shoes are dry. Sit in a comfortable position in a manner that lets you reach the controls with ease.

Always keep in mind that forklifts have a center of gravity shared with the load it’s carrying. All forklifts have a three-point suspension system also known as the stability triangle. Operators must stay within the stability triangle to keep the truck from tipping over. As the weight of the load increases, the center of gravity gets tipped off to one side, reducing the lifting capacity of the forklift.

5. Keep out of the forklift’s hazardous areas.

When carrying a load, avoid standing or walking under a load, forklift attachment, or lifting mechanism. This poses danger as loads can fall on anyone situated below it. Never place your hand from the forklift mast, as a moving mast can injure your hand.

Minimize the risk of dangerous forklift under-rides. Install a forklift rear post acquired from lakeportmetalcraft.com to protect forklift operators from being struck by objects while driving the truck. Rear posts create a physical barrier between the staff and horizontal cross beams to prevent physical injuries.

In addition to adequate training, employers can increase employee safety by ensuring regular forklift maintenance and clearing the workplace from obstacles and distractions. Addressing safety issues boosts employee morale, enhancing productivity and efficiency in the workplace.